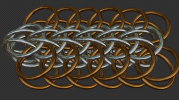

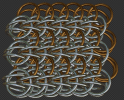

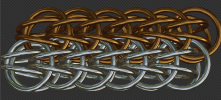

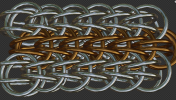

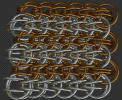

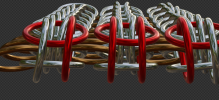

Hey guys! It has been a really long while since I've posted something, and I would post pictures, but obviously I cannot. I stumbled upon this while trying to mess around with Full P6-1, as one does I suppose. Anyway, I found that if you insert a tether between the rings "protruding" on the top section of the picture, and shown "flat" on the bottom, you can link multiple of these chains together. Depending on your aspect ratio, you can do this on both faces. What results is a very nice sheet that is fairly thick and looks very nice. It curls more on one end than the other if you only tether one side. I would like to call the band created by four tethers on each unit by the name, "firecracker", as that's just something it reminds me of. It is possible to tether these chains together in several ways. But doing so in the way I described is the most orderly as the tethers do not jangle around. The sheet produced looks something like dragon scale. Assuming you only tether it on one face, you end up with what looks like scales on one face, and a twill weave on the other. It looks so very nice, and is so very nice to handle. By virtue of the protruding rings, that are sort of perpendicular to the plane of the sheet, it rolls fairly smoothly in a certain direction.

The sheet produced, I would propose to be named, "Tethered Full Persian 6-in-1 (Grizzly)". But as this is *really* wordy, I would also propose an alternate name, Grizzly scale. There are multiple ways to tether this sheet however. Assuming you only tether one face, it could be considered "half" in some regard, but I think the fractions involved in Persian weaves make that terminology confusing. You could also alternate the face on which you tether the chains, which reminds me of a box pleat. I wouldn't call it that either because it kind of sounds like "box chain", which it is not.

I don't know if this should be a new post entirely, and I'm sorry for the long post here in the discussion section.

The ring specifications I use to make this were 20awg, half-hard, red brass, round wire, wound around a 6mm steel rod. The spring back was not enough to allow the rings to fit around a 7 mm rod.

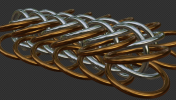

When single-sidedly tethered, the sheet is fairly loose at a small size, but experiences greater lock up as the chains are lengthened. I noticed this because I was able to create a cylinder, but as I unwrapped, lengthened, and then tried to re-wrap the sheet back into a cylinder, I found I needed to add more columns of FP6-1 (grizzly) chain.

Doing a full four tether rings on each unit at the end of a chain makes a very nice termination to the chain. This is what I would like to call the "firecracker" band.

I'm a little bit more busy recently, but I'll be happy to answer any questions anyone has. I might take a while to respond though.

The sheet produced, I would propose to be named, "Tethered Full Persian 6-in-1 (Grizzly)". But as this is *really* wordy, I would also propose an alternate name, Grizzly scale. There are multiple ways to tether this sheet however. Assuming you only tether one face, it could be considered "half" in some regard, but I think the fractions involved in Persian weaves make that terminology confusing. You could also alternate the face on which you tether the chains, which reminds me of a box pleat. I wouldn't call it that either because it kind of sounds like "box chain", which it is not.

I don't know if this should be a new post entirely, and I'm sorry for the long post here in the discussion section.

The ring specifications I use to make this were 20awg, half-hard, red brass, round wire, wound around a 6mm steel rod. The spring back was not enough to allow the rings to fit around a 7 mm rod.

When single-sidedly tethered, the sheet is fairly loose at a small size, but experiences greater lock up as the chains are lengthened. I noticed this because I was able to create a cylinder, but as I unwrapped, lengthened, and then tried to re-wrap the sheet back into a cylinder, I found I needed to add more columns of FP6-1 (grizzly) chain.

Doing a full four tether rings on each unit at the end of a chain makes a very nice termination to the chain. This is what I would like to call the "firecracker" band.

I'm a little bit more busy recently, but I'll be happy to answer any questions anyone has. I might take a while to respond though.